Abstract

장치설비는 maintenance 수명주기비용(Life Cycle Cost)이 가장 큰 설비이며 국부적 부식, 마모 등에 따라 수명이 크게 단축되기도 한다. 고가의 고급재질로 upgrade하는 효과 이상을 갖는 방안이 표면 강화 Clad Coating 기술이다. 운전조건, 부위별 침식 상태에 따라 내구성의 융복합 재질로 특성 부여함으로써 적은 비용으로도 가성비 최상의 조건을 갖는다.

Property

• Anti-Corrosion/Erosion/Fouling

• 유체 tailored clad coating

• Graphene diffusion Coating

• SCC, HIC, CUI, Strong acid & base Solution

• On-Site Work

• 유체 tailored clad coating

• Graphene diffusion Coating

• SCC, HIC, CUI, Strong acid & base Solution

• On-Site Work

Anti-Corrosion

| HF NaOH HCl NH4Cl H3PO4 H2SO4 |

▪ 100% 全농도 ▪ Up to Boiling point |

Trouble Shooting

Material

Carbon steel

SUS 316L

Duplex+

CD4M

Inconel & Monel

Titanium

Glass Linning

SUS 316L

Duplex+

CD4M

Inconel & Monel

Titanium

Glass Linning

Trouble

Corrosion

Erosion

Oxidation

Fouling

SCC

HIC

CUI

Erosion

Oxidation

Fouling

SCC

HIC

CUI

Solution

융복합재

Cermet. Super Alloys

Nano Ceramics

Fluoropolymers

Advanced Polymer

Graphene

Zirconium Alloy

Tantalum

Cermet. Super Alloys

Nano Ceramics

Fluoropolymers

Advanced Polymer

Graphene

Zirconium Alloy

Tantalum

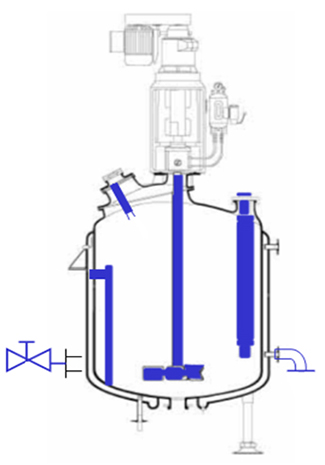

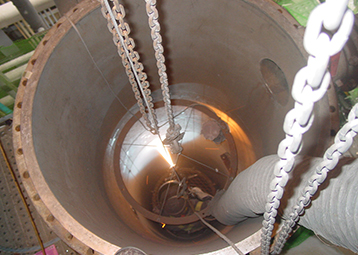

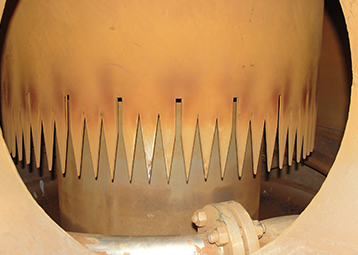

Reactor

Zr + Graphene Coating

Performance – 개선 주요 사례

Vent Gas Wash Tower

Trouble Point

• HCl Crevice Corrosion

Solution

• Anti-Corrosion/Erosion Fouling

Water Seal Drum

Trouble Point

• HF Corrosion

Solution

• Anti-Corrosion

Reactor Tank

Trouble Point

• Teflon Lining peel off

Solution

• Anti-Corrosion/Erosion Fouling

Heat Exchanger

Trouble Point

• H2SO4 Crevice Corrosion

Solution

• Anti-Corrosion

Application

• Reactor

• Agitator

• Agitator

• Storage Tank

• SCC Vessel

• SCC Vessel

• Pipe Line

• Fitting

• Fitting

• Tower

• Column

• Column

• Chute

• Stack

• Stack

• Thermal Cracking Process

• Heat Exchanger

• Heat Exchanger